Expertise

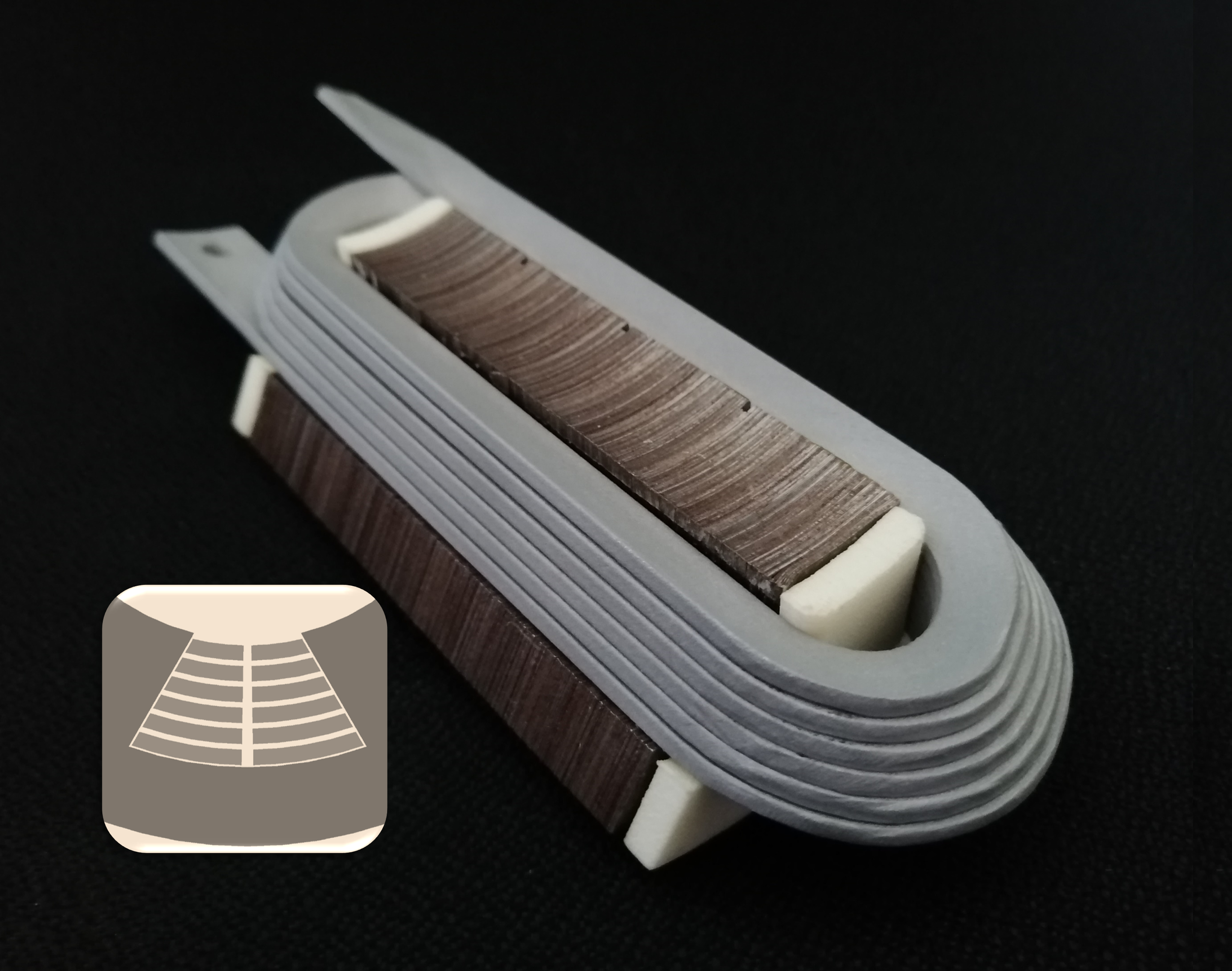

Innovative Winding Designs

High Electromagnetic performance

From compact radial flux coils to axial flux coils, each solution is shaped for maximum performance. Drive13 develops advanced coil shapes that reduce losses, boost efficiency, and reduce weight. Learn more

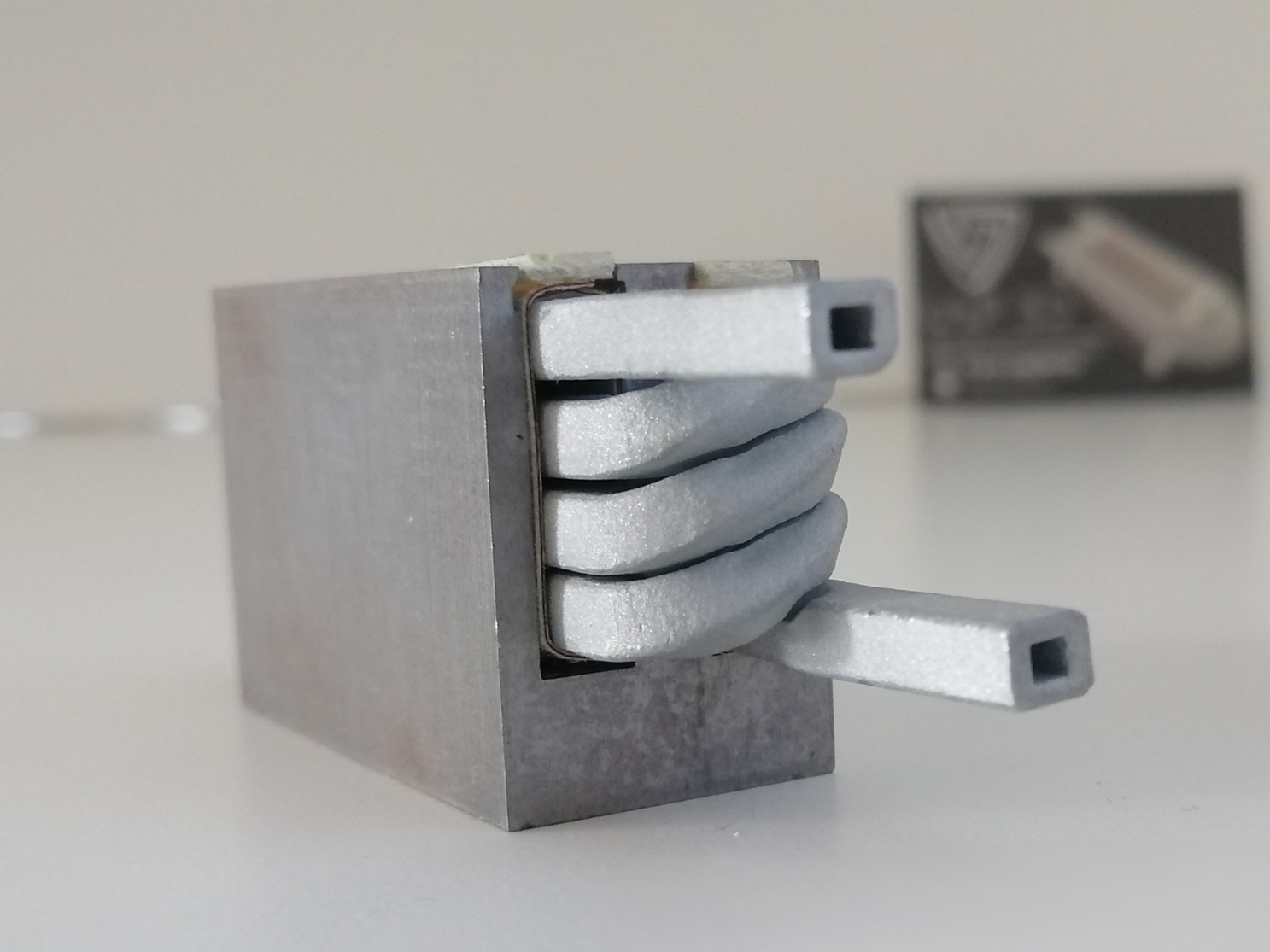

Improved Thermal management

Our cooling solutions effectively improve heat evacuation and enable the motor to operate contentiously at higher speeds without overheating. Whether through built-in channels, heat exchangers, or hollow coils, we ensure better temperature control and reliability. Learn more

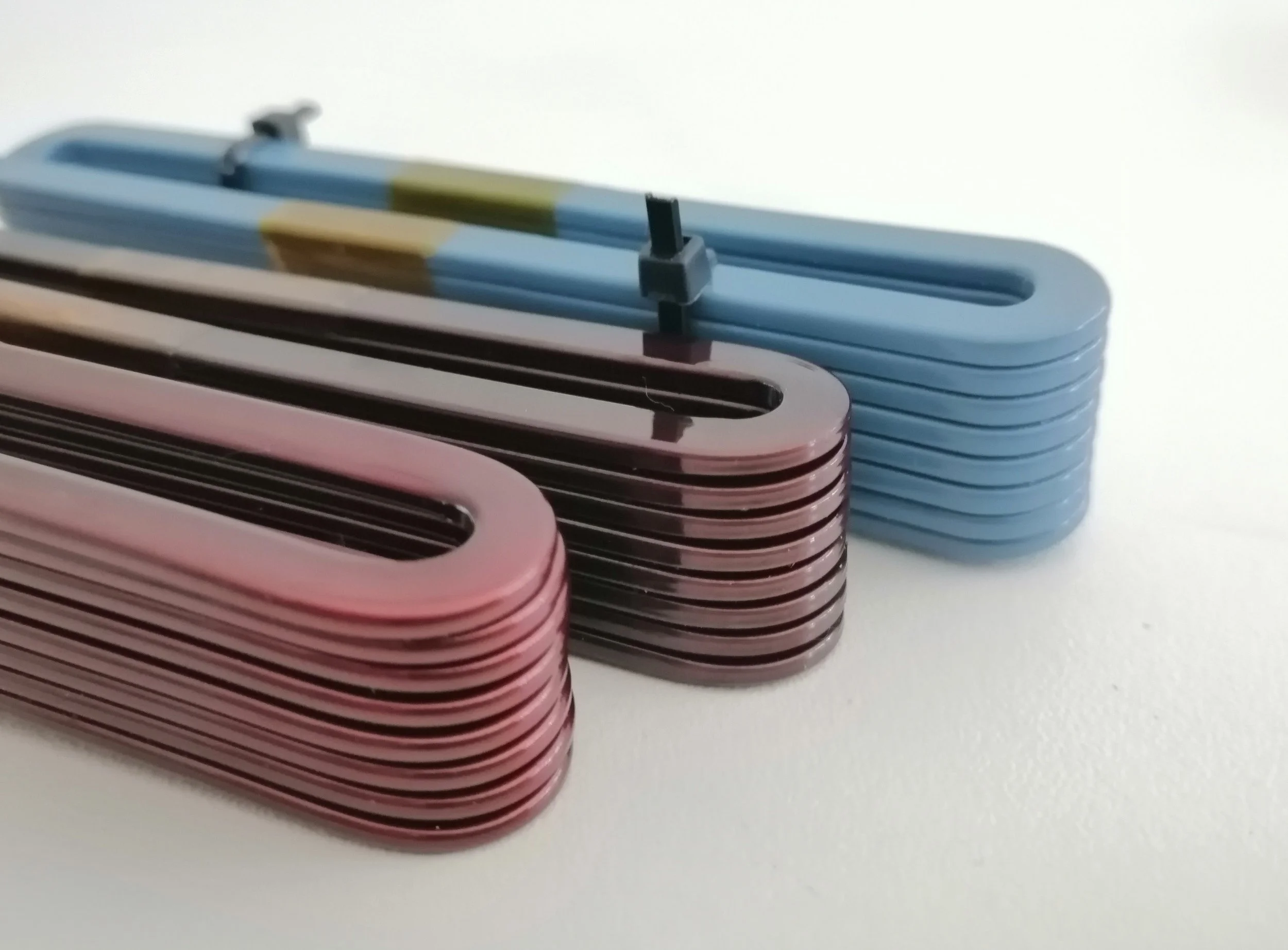

Specialized Custom Solutions

From lightweight hairpin windings to built-in busbars and high altitude coils, we adapt to your most specific needs. Learn more

Durable Electrical insulation

Unique approach for unmatched quality

Conventional tooled coil

Proprietary

in-house coating technology

All our coatings are applied after shaping the coil. This unique approach eliminates mechanical tension and prevents cracks in the insulation—resulting in unmatched performance, exceptional durability, and long-term reliability.

Wide variety of Best-in-Class materials

We offer a broad portfolio of advanced coating solutions, engineered to meet the most demanding applications. Our premium insulation technology delivers exceptional durability, withstanding temperatures up to 260°C. Each coating system is carefully customized to your specific application, ensuring optimal protection.

Full in-house development and production

With 100% control over every process parameter, we guarantee the highest production quality. Our in-house capabilities enable precise control of film thickness, ensuring optimal insulation performance. The result is a fully functional component, which is verified and tested to meet the needs of your specific application.

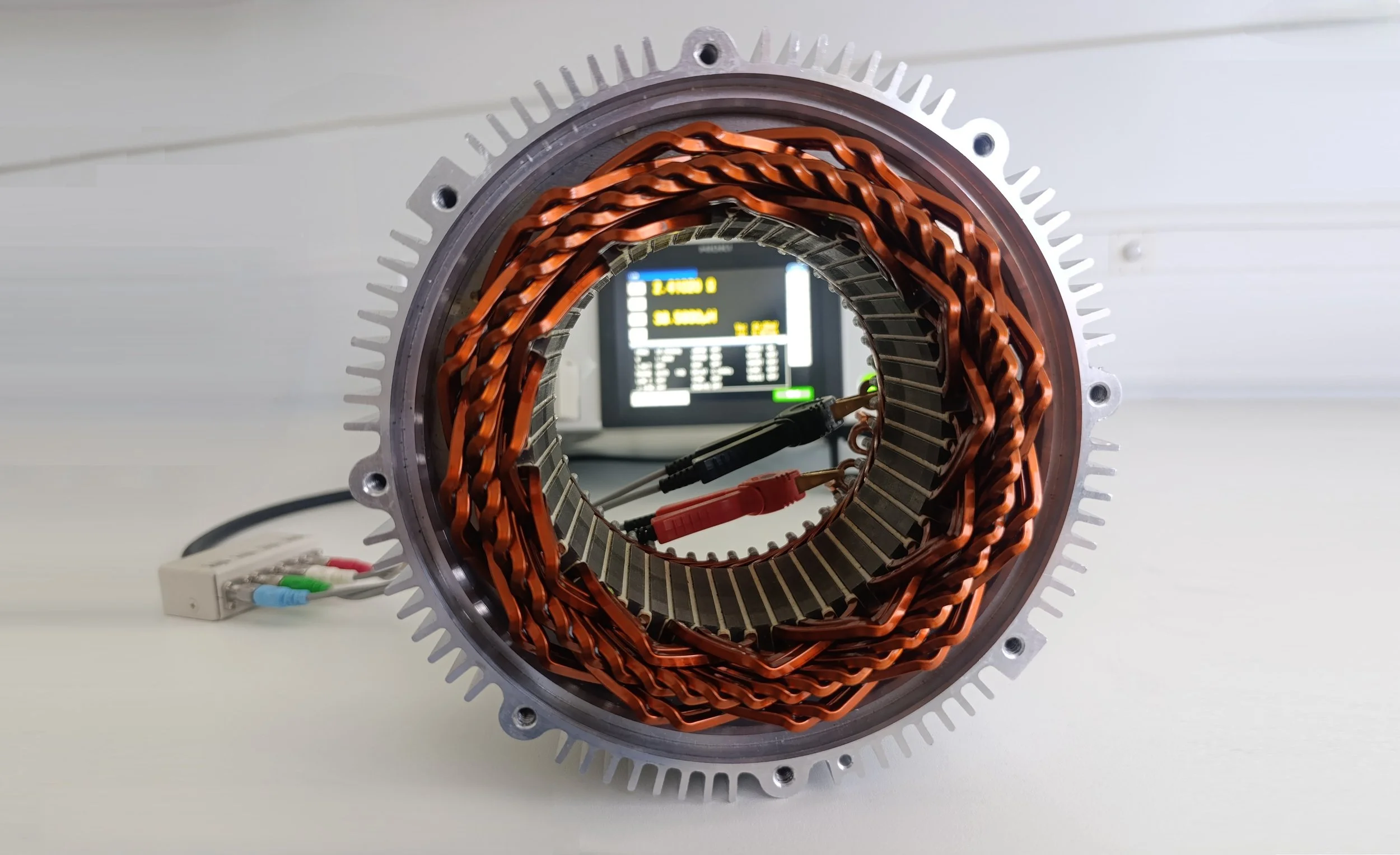

RESEARCH, DEVELOPMENT & ENGINEERING

In-house design tools for optimization of Electrical Machines

Our multi-disciplinary development team has a broad experience in the modelling, designing, prototyping, and testing of complete electrical machines. That in-house expertise ensures fast design cycles and significantly reduces lead times from concept to execution.

Testing, Validation, Quality Assurance

we can perform a wide range of tests—covering everything from material-level and insulation validation to full motor performance mapping such as power, efficiency, and endurance evaluation. Our testing protocols include worst-case scenario conditions, ensuring that every component meets the highest standards of durability and operational excellence in the most demanding environments. These capabilities are further strengthened through our collaboration with UGent, enabling access to advanced testing facilities and expertise.

Get in touch

It all begins with an innovative idea. Maybe you have a creative project to start. Whatever it is, our team will be happy to support your ongoing developments.