OFFERINGS

co-development service

Customizing innovative E-motor prototypes

As an engineering partner to OEMs and TIER1 companies, Drive13 designs, develops, and manufactures motor components tailored to customer-specific requirements. From advanced 3D printed aluminum windings to complete E-motor assemblies and sustainable remanufacturing, Drive13 provides a full spectrum of solutions tailored to performance, scalability, and lifecycle efficiency.

-

Drive13 follows a " Concept to Commercialization" approach, ensuring a structured and efficient development process:

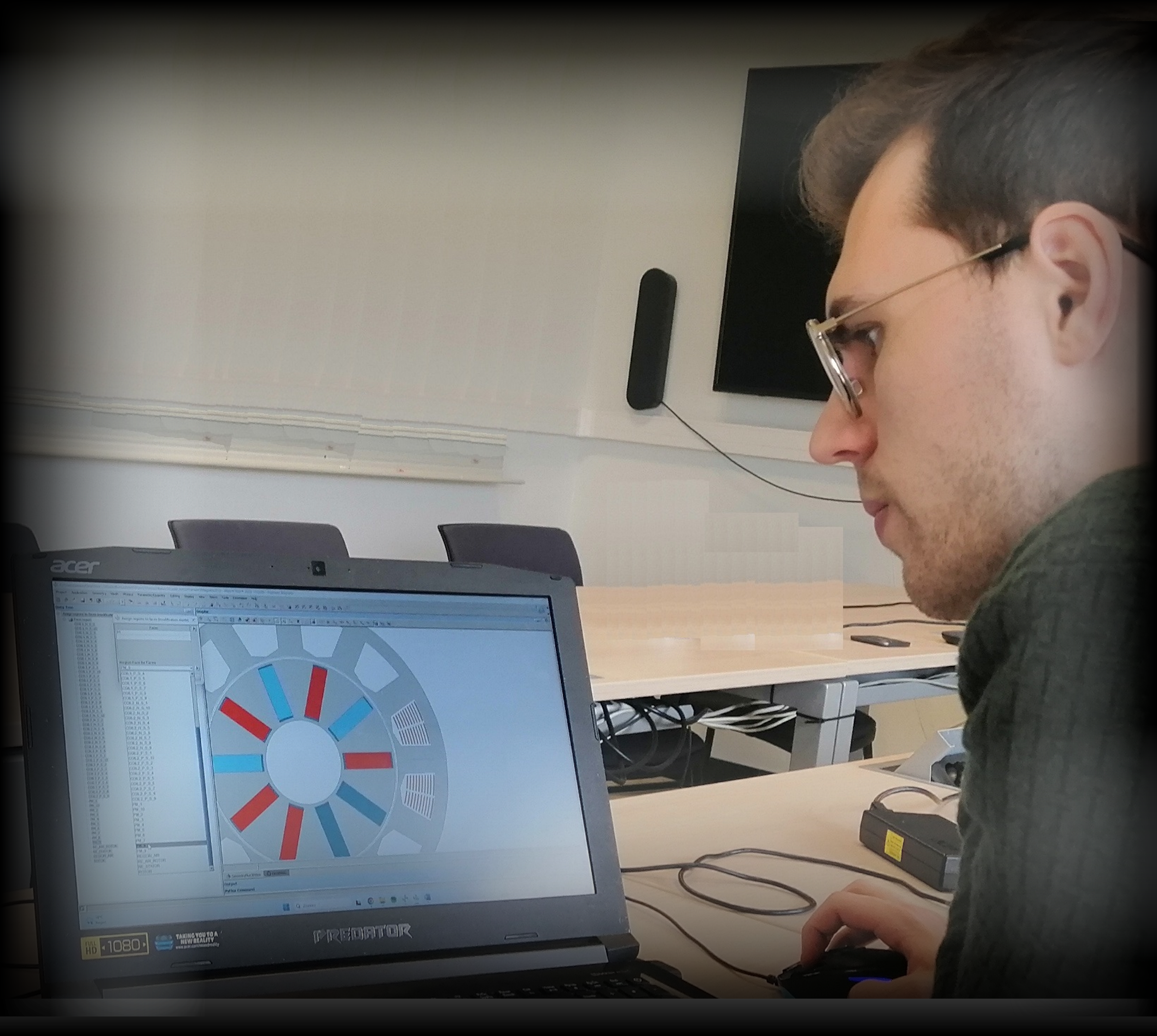

Electromagnetic and thermal simulations

Multidisciplinary design optimization

Custom Winding Prototyping

Electromechanical Integration

Test Cycles & Validation

Our mission is to deliver optimized components and innovative system-level solutions that precisely match your performance targets, cost constraints, and manufacturing requirements.

-

Our vertically integrated capabilities support customers from functional prototype development and assembly through the first steps toward series production.

we offer:

Integration of the windings and the stator

Busbar connections

Impregnation of thermal management

Prototyping of the rotor, PMs, and housing, and mechanical interfacing

We deliver full prototype motors that help accelerate your path to production.

-

We help customers extend product lifecycles by remanufacturing components, restoring them to original or upgraded specifications—reducing waste, enhancing sustainability, and improving cost-efficiency without compromising performance.

Winding set production

Manufacturing complete coil system

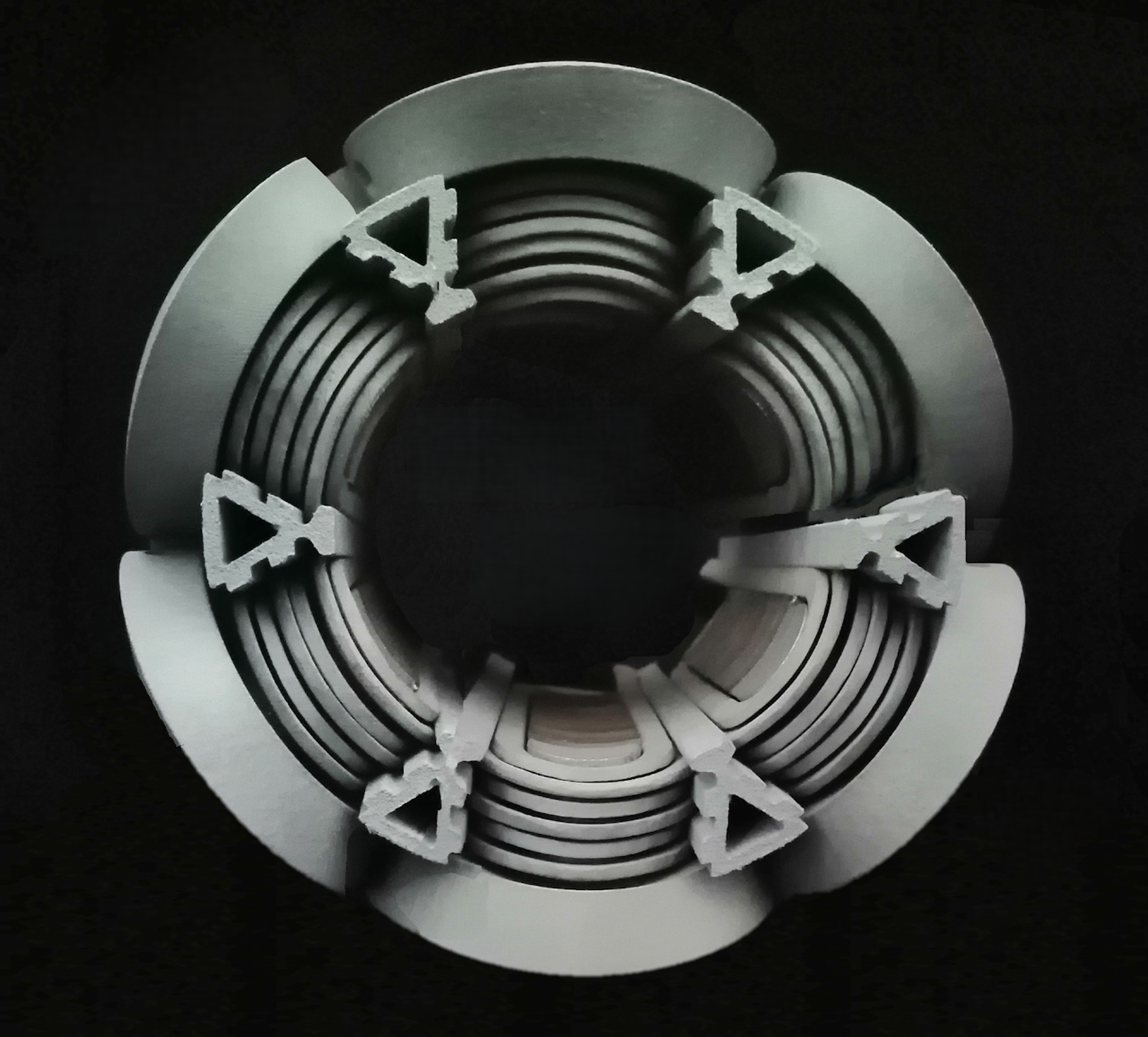

Drive13 delivers complete, ready-to-install, functional winding sets, whether for one-off unique prototypes or product series. Our process begins with 3D printing of windings to exact customer specifications. Each winding is then finished with a carefully selected advanced coating, applied entirely in-house to maintain full control over quality. Finally, every production set is subjected to our standardized quality assurance tests to verify performance.

-

We specialize in the rapid prototyping of lightweight, additively manufactured aluminum windings, engineered for high-power density and thermal efficiency.

Ideal for early-stage development, concept validation, and performance testing.

-

We offer a wide range of high-performance insulation materials, engineered for exceptional results in the most demanding environments.

Sampling

Feel the winding quality

Order a standard Sample Set

Experience the performance and quality of our 3D printed aluminum windings. Our standard sample box includes 4 fully coated and functional windings. Perfect for technical evaluation, prototyping, or internal benchmarking.

Looking for a specific geometry or coating material? We offer fully customized samples tailored to your project needs.

Define your specifications — we’ll deliver a functional coil sample, custom-built to your requirements.

Fully custom geometry and dimensions

Fast engineering support and printability assessment

Choice of advanced functional coatings

Ready to build your own sample?

Upload your specifications and get a quote

Customize Your Own Design

Get in touch

Our team will be happy to support your ongoing developments.