RESEARCH, DEVELOPMENT & ENGINEERING

Design & Engineering

1

Early involvement of the Drive13 R&D team ensures seamless integration and fast execution. Our state-of-the-art digital chain tools enable rapid selection of best-in-class solutions, accelerating innovation while reducing time-to-market.

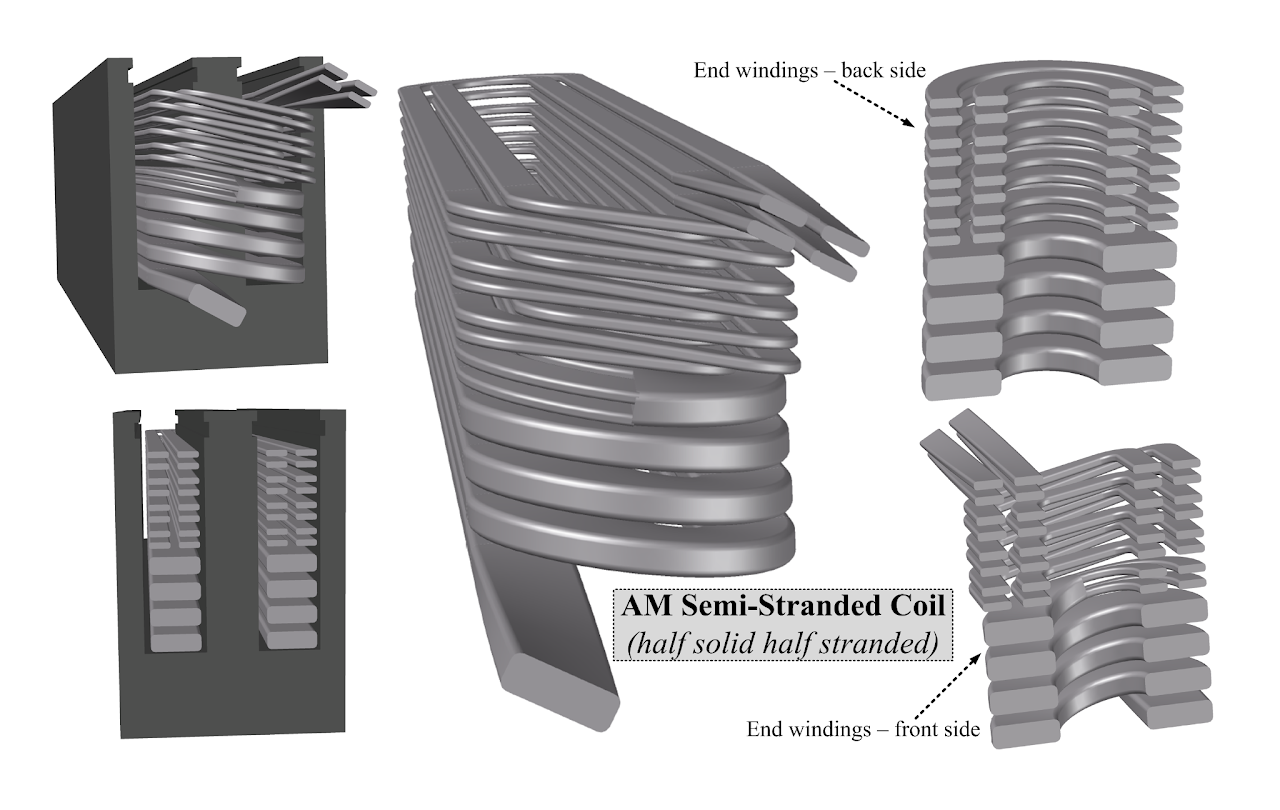

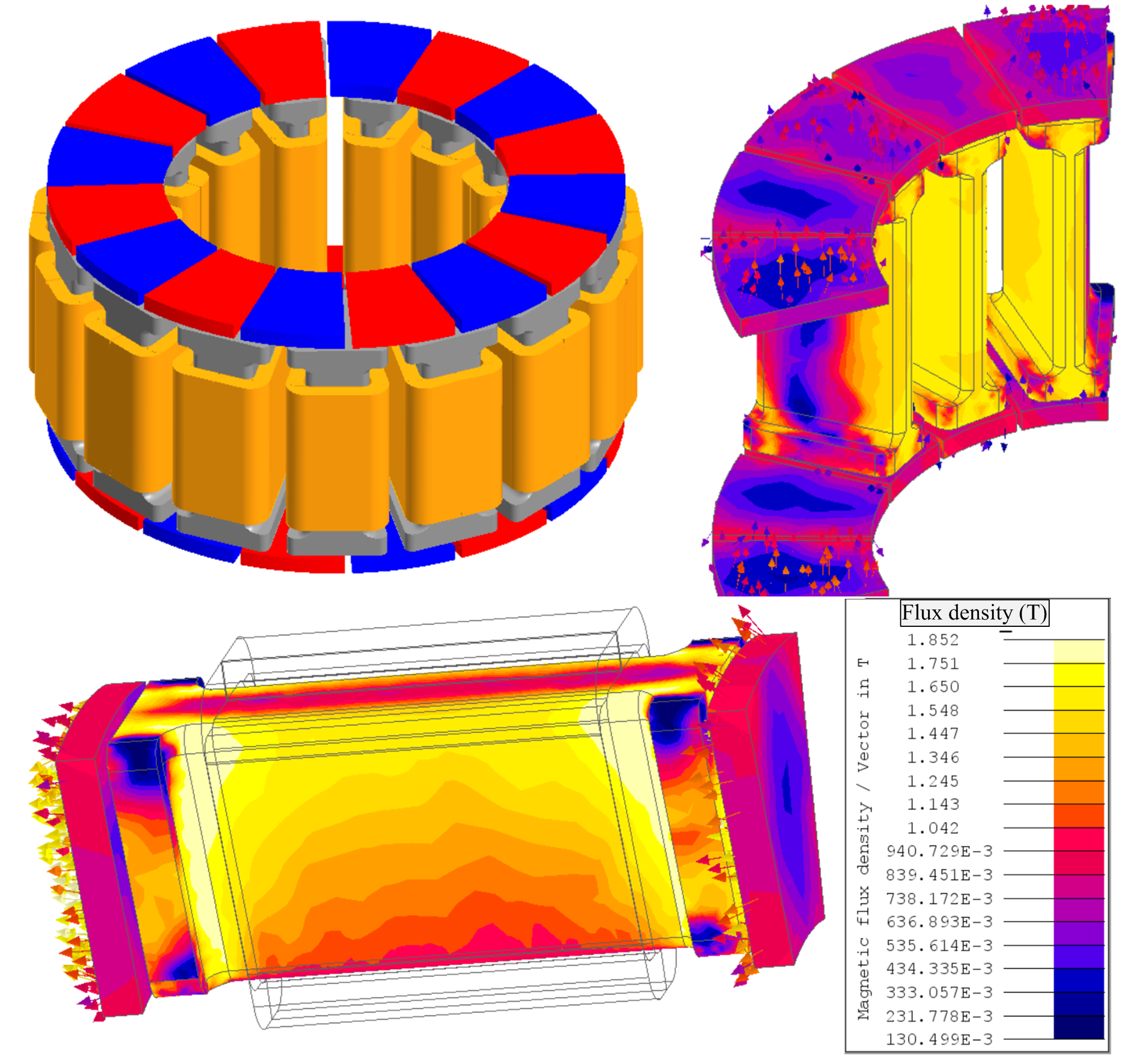

Design and Optimization of Electrical Machines

Multi-disciplinary design optimization of full E-motors

Optimal balance between losses, weight, and cost.

Higher power density (above 25 kW/kg).

Material tradeoff and selection of best-in-class solutions.

Free shape optimization of windings at stranded level.

Unmatched efficiency for radial and axial flux machines.

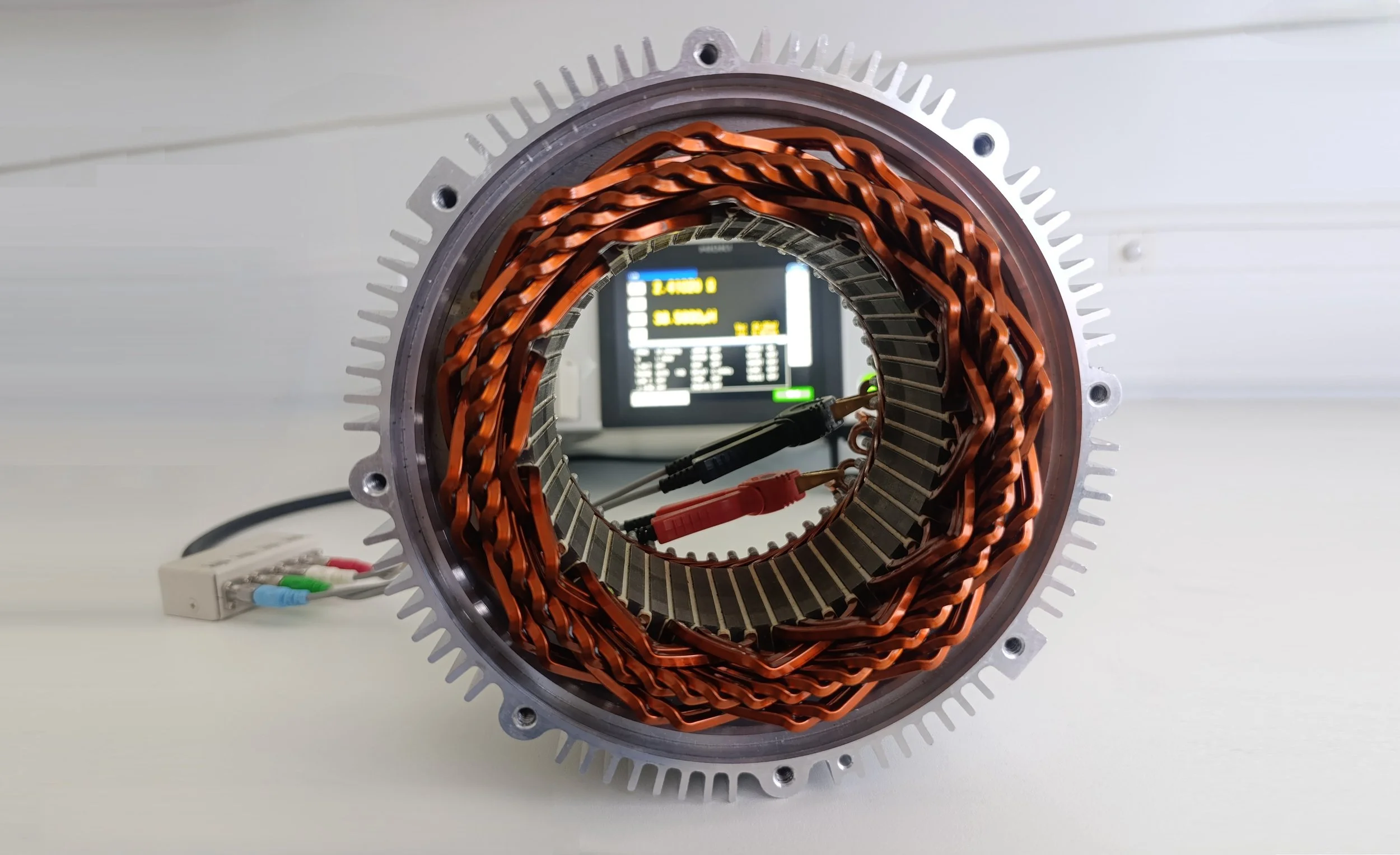

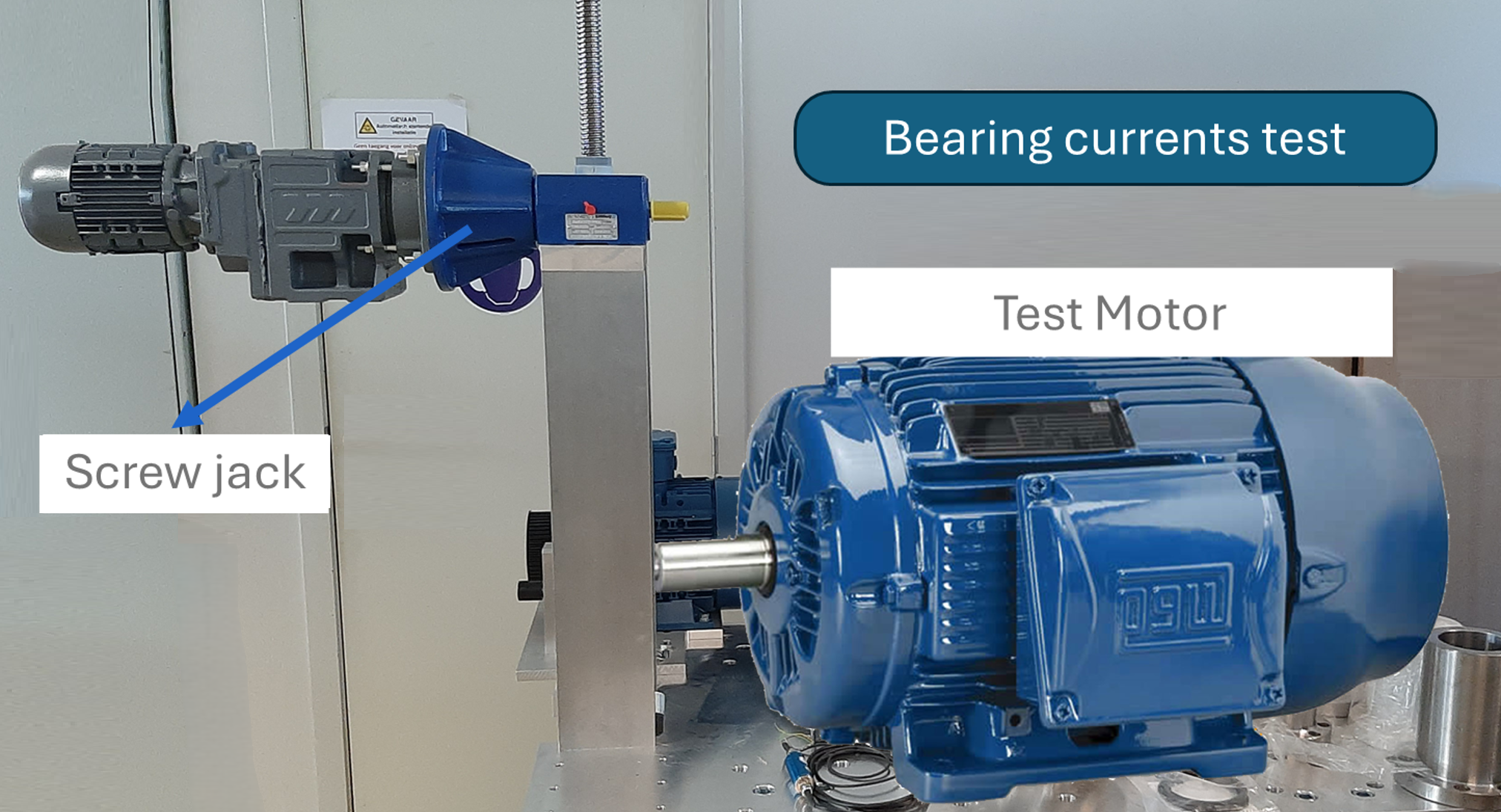

Testing & Validation

2

Test cycles & quality assurance

we can perform a wide range of tests—covering everything from material-level and insulation validation to full motor performance mapping such as power, efficiency, and endurance evaluation. Our testing protocols include worst-case scenario conditions, ensuring that every component meets the highest standards of durability and operational excellence in the most demanding environments. These capabilities are further strengthened through our collaboration with EELAB, enabling access to advanced testing facilities and expertise.

Functional testing to ensure compliance with industry standards:

Electric Test: AC high frequency losses

Core loss separation and magnetic material characterization

Efficiency map

Insulation quality: partial discharge inception voltages (PDIV Test)

Endurance test and lifetime assessment

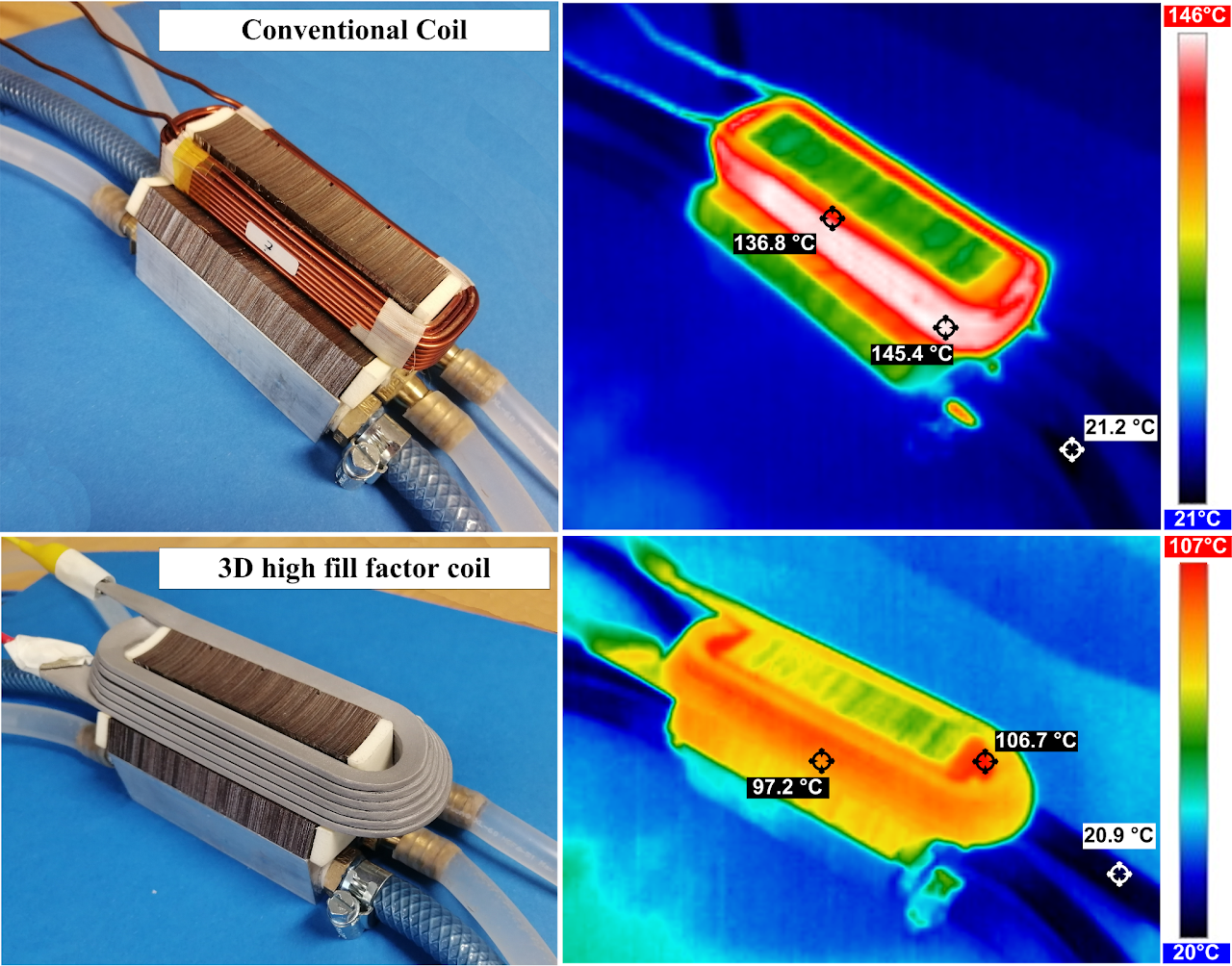

Custom thermal tests

Testing heat evacuation at rated conditions

Get in touch

Our team will be happy to support your ongoing developments.