A Sharp Approach for Thermal Validation

In our playbook, a motor wire can carry 1000 Amp, if you provide the right ‘Cooling’ and the right ‘Coating’.

The challenge is proving that your cooling and coating stack can handle that – quickly, safely, and without building a full prototype machine every time you change a material.

From Full Motor Test to Smart Motorette

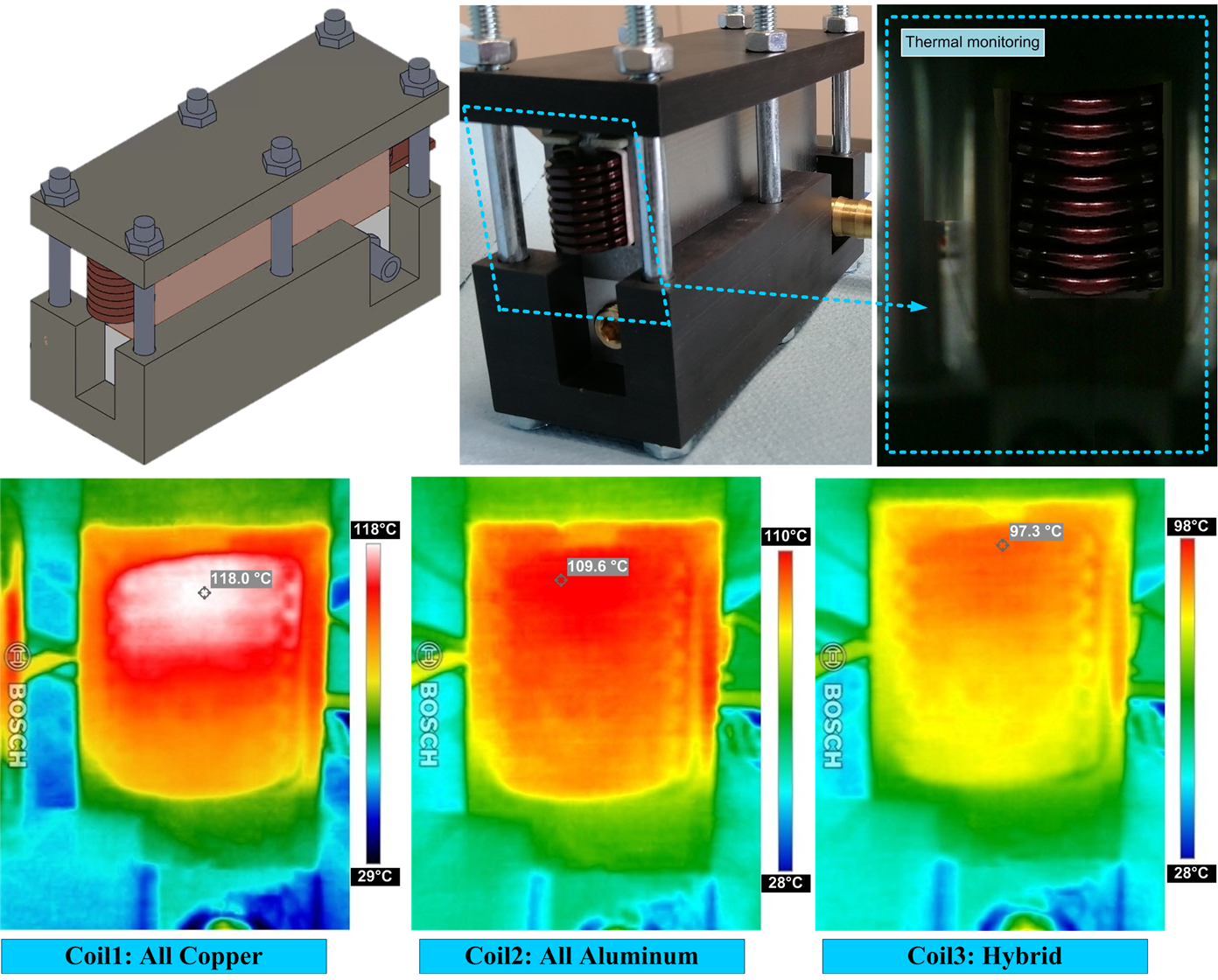

In our latest paper, we introduce a sharp, motorette‑based method to validate the thermal behaviour of new winding concepts.

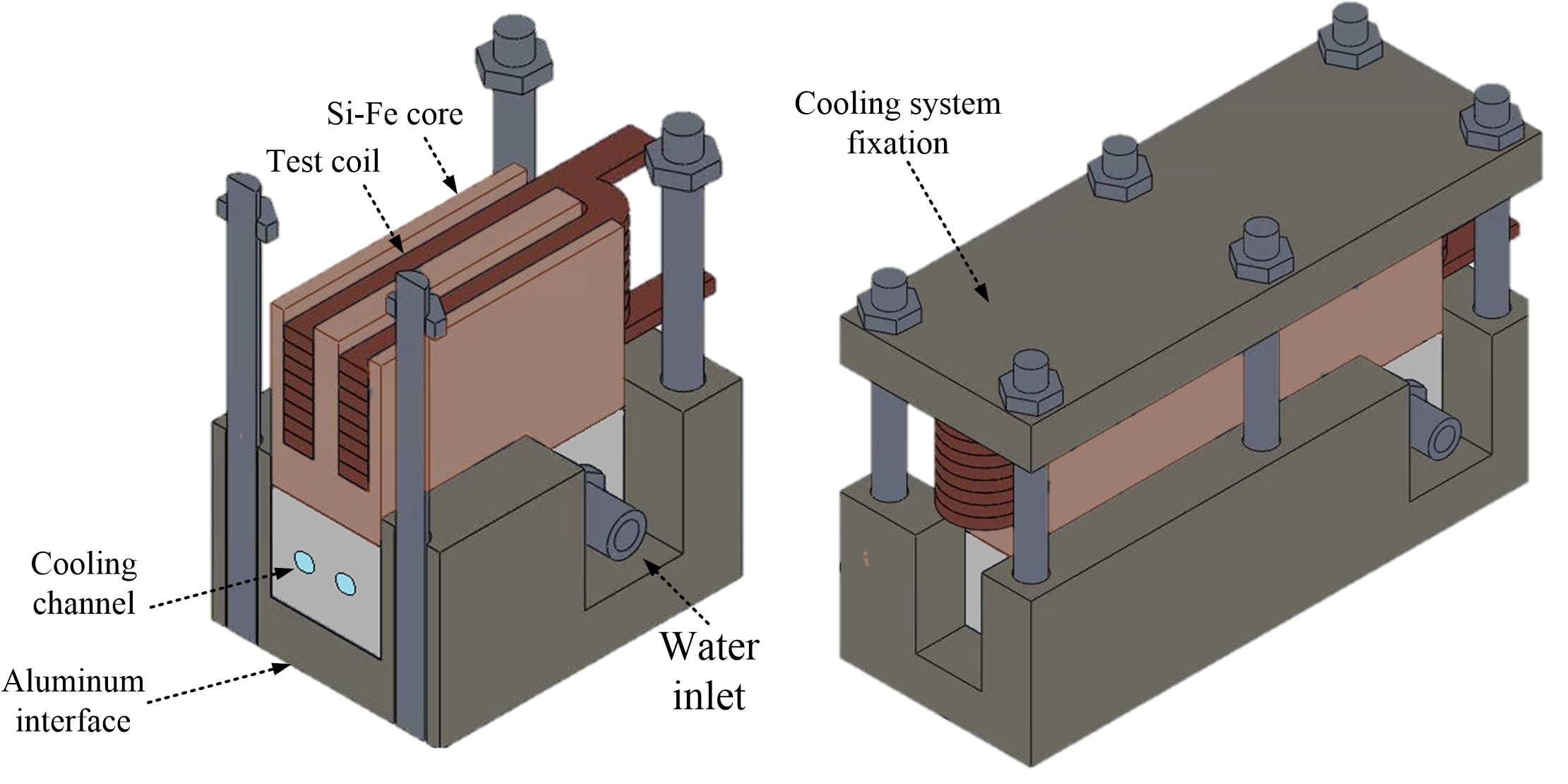

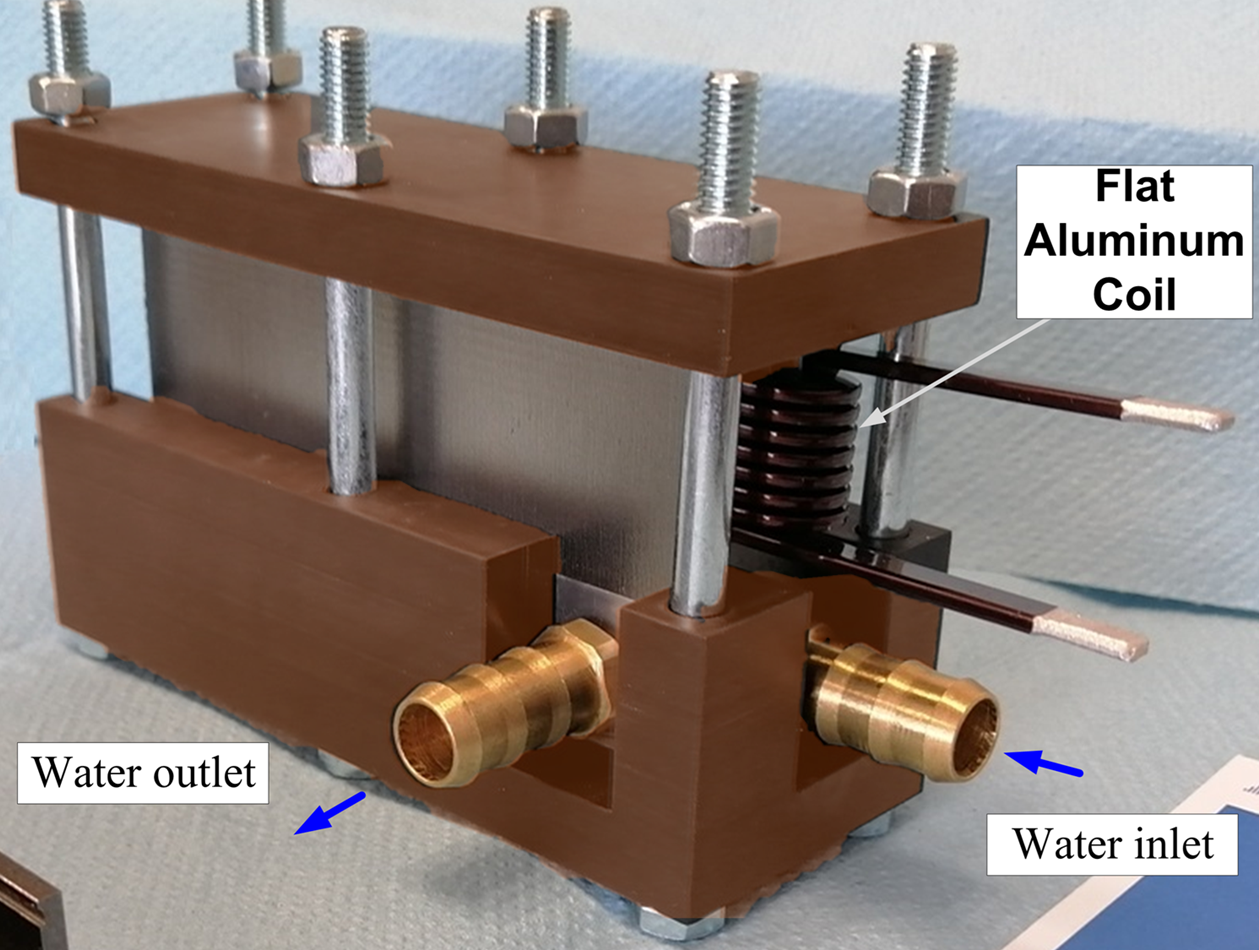

Instead of assembling a complete motor, we work with a dedicated 2‑slot motorette:

Realistic E‑core with the same slot geometry as the target machine

Dedicated aluminum cooling jacket with dual channels and forced water convection

Flat conductors (Cu, Al, or hybrid) with real slot liners, primary insulation and impregnation

Embedded PT100 sensors and thermal camera coverage for detailed hotspot mapping

This compact setup recreates the true 3D heat path from winding → insulation → slot liner → impregnation → cooling jacket – but is fast to build, easy to modify and highly repeatable.

Fast Loop: Model → Test → Material Decision

Behind the hardware sits a fully parametric electro‑thermal FE model of the winding and cooling jacket. Thousands of design combinations—conductor mix, strand dimensions, jacket geometry, coolant conditions—are screened virtually, then a shortlist is validated on the motorette.

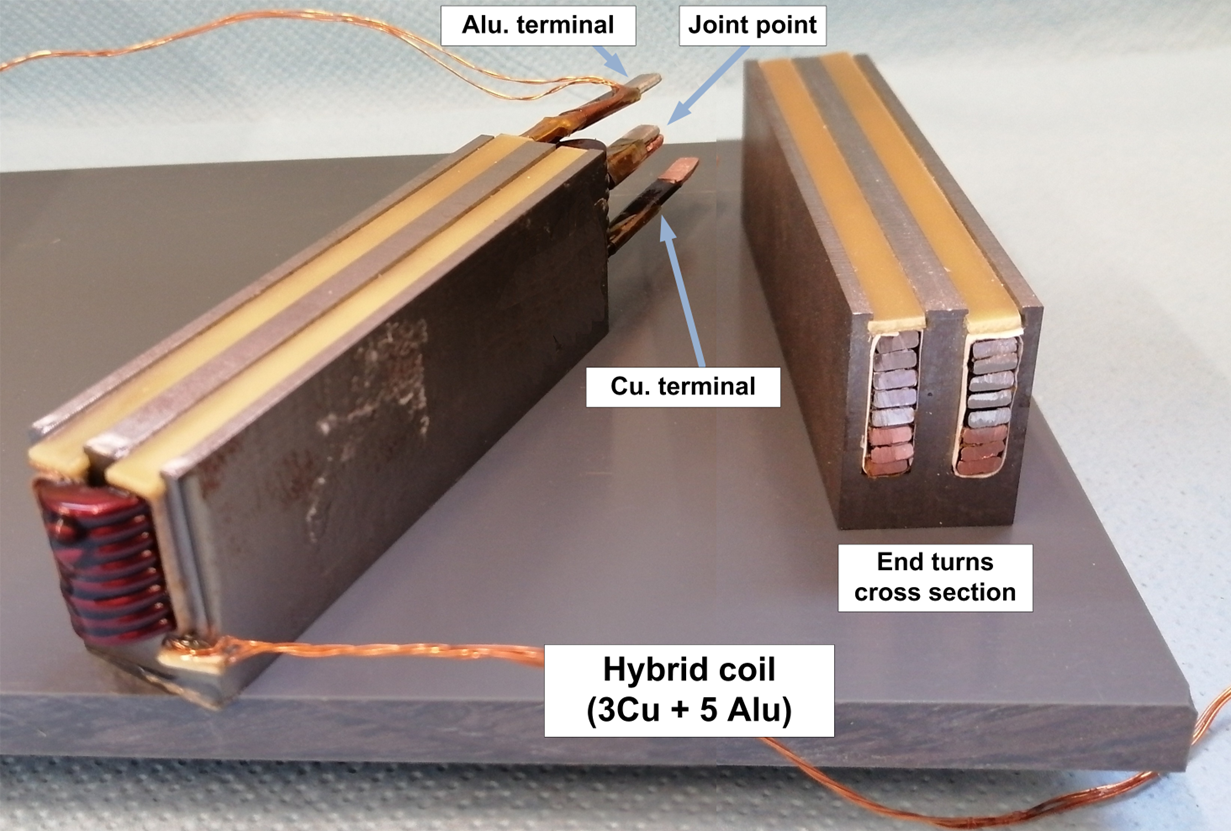

We validated three coil types:

Full copper

Full aluminum

Hybrid (Cu at the slot bottom, Al towards the slot opening)

Under WLTC‑based load profiles, the hybrid coil showed up to ~18% lower hotspot temperature vs. a pure copper coil at worst‑case operation, while cutting winding weight and boosting machine power density.

The key point: you can now verify your thermal model and test several material directions without the burden of testing a full machine.

What This Unlocks for You

In our recently published work, we’re effectively offering a quick and accurate thermal check for your e‑motor design choices:

Key benefits

Hotspot allocation & worst‑case scenario testing

Identify where your real thermal limits are – in the end windings, upper slot conductors, or at the cooling interface.Validation of overall thermal conductivity chain

Confirm how your full stack behaves as a system:

Winding → primary insulation → impregnation →slot liner → stator core→ cooling jacketRapid material and concept screening

Try different impregnation systems, insulation grades, Cu/Al mixes, or cooling concepts with minimal hardware investment.Scalable to very high current levels

Confidently explore designs where each conductor is expected to carry extreme current – as long as cooling and coating are engineered and validated accordingly.

If you’re developing next‑generation, high‑power‑density drivetrains and want to de‑risk them thermally—before committing to a full prototype machine—our motorette‑based thermal validation approach is built precisely for that.

Want to validate your next coil concept?