Find Your Champion magnet

In our playbook, A strong magnet is not always the best magnet.

When people ask, “What is the best magnet?” they usually have one hero in mind: 🧲 Neodymium

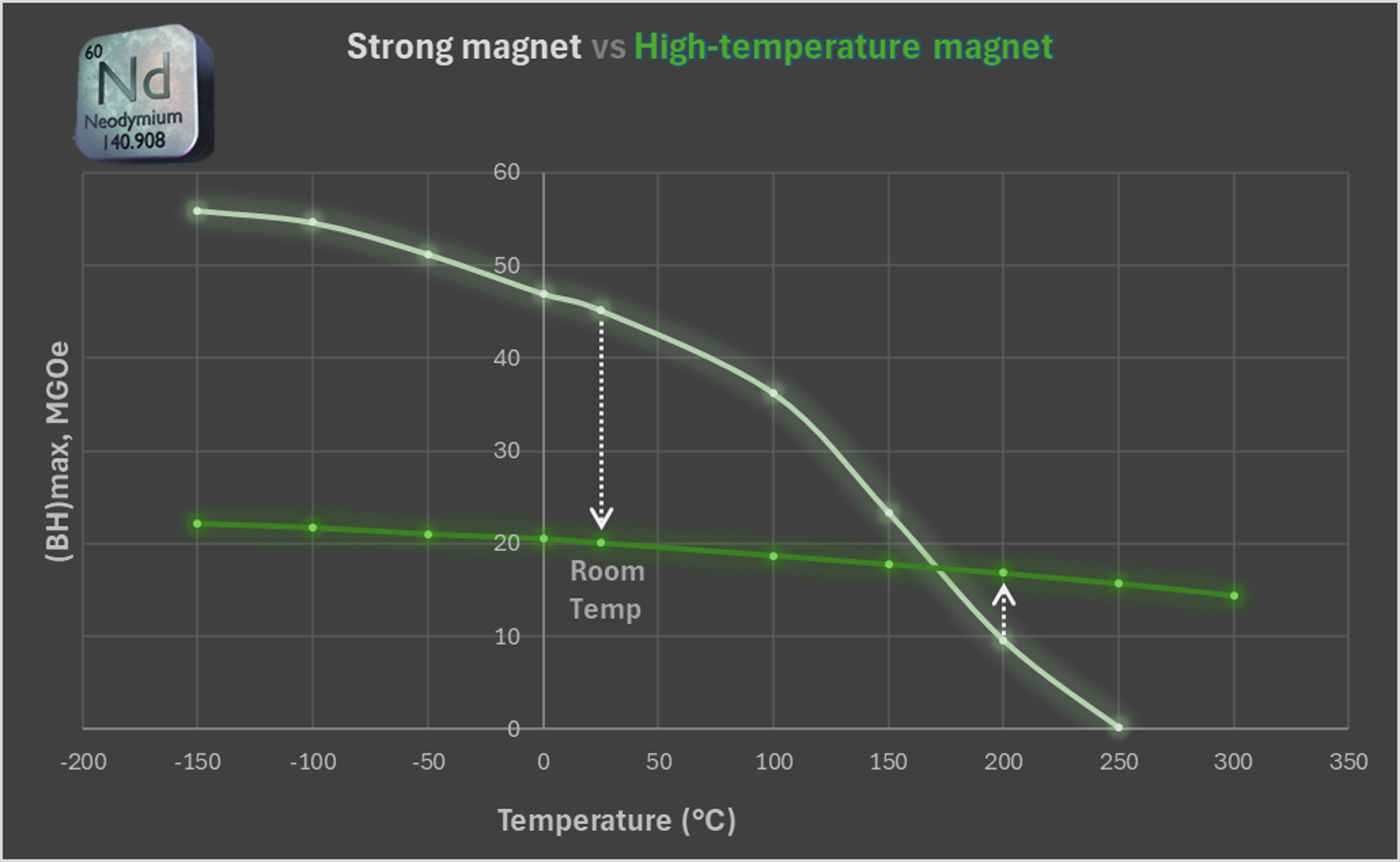

NdFeB is the strongest permanent magnet — but only at ‘room’ temperature.

In reality, best is never one-dimensional. The ideal magnet for an electric drive, sensor, or actuator depends on:

Magnetic strength (remanence, coercivity, BHmax)

Operating temperature and thermal stability

Risk of demagnetisation in the application

Cost and supply security

Environmental footprint

So the real question is: what is the best magnet for your job?

The “Strongest” Magnet vs the “Greenest” Magnet

A strong Magnet

Neodymium-iron-boron (NdFeB) magnets are usually the answer when strength per volume matters:

High coercivity & high BHmax → very high torque density in compact motors

Cheaper per unit of performance than many alternatives

Low minimum order quantities (MOQ) and short lead times in standard grades

That’s why NdFeB is ubiquitous in e-motors, robotics, wind turbines, and consumer electronics.

But this is only half the story.

A Green magnet

A green magnet is not necessarily the absolute strongest at 20 °C. Instead, it is optimized for performance and:

High functional performance in the real duty cycle

Low and transparent carbon footprint (CF)

Local & stable, closed-loop supply chains

Recyclable or reusable at end of life

Minimal heavy rare earth element (HREE) content

In other words, the “best” magnet may be slightly less powerful on paper but more robust, more sustainable, and less risky in the long run.

HREE: Heavy Rare Earth Elements: Strength at a Cost

To make magnets survive higher temperatures and strong demagnetising fields, NdFeB is often doped with heavy rare earth elements (HREE) such as:

Dysprosium (Dy), Terbium (Tb), Gadolinium (Gd), Samarium (Sm), Lutetium (Lu), Scandium (Sc), Yttrium (Y)

These elements increase coercivity, especially at high temperature, but they are:

Scarce and geographically concentrated

Expensive and price-volatile

Environmentally and socially challenging to mine

That is why green magnet design tries to minimize HREE content, using them strategically only where they unlock clear, indispensable performance.

A Practical TOOL: select your Champion Green magnet

To move beyond marketing labels, a magnet choice should be driven by quantifiable targets.

Key inputs:

Target remanence, Br (T)

For high torque, you may need higher Br to achieve the desired air-gap flux.Target coercivity, Hc (kA/m)

For low risk of demagnetisation, especially in high-load or fault conditions.Target temperature, Tmax(°C)

Maximum continuous operating temperature for your application (including overload and hot-spot margins).Target HREE content

Maximum acceptable heavy rare earth content (wt%) linked to sustainability, cost, and supply-chain risk.

Such a selection tool does not tell you “use this brand”; it helps you navigate the trade-off space between strength, temperature, risk, and sustainability and pick your own “champion” magnet.

Permanent Magnet Grade Selector

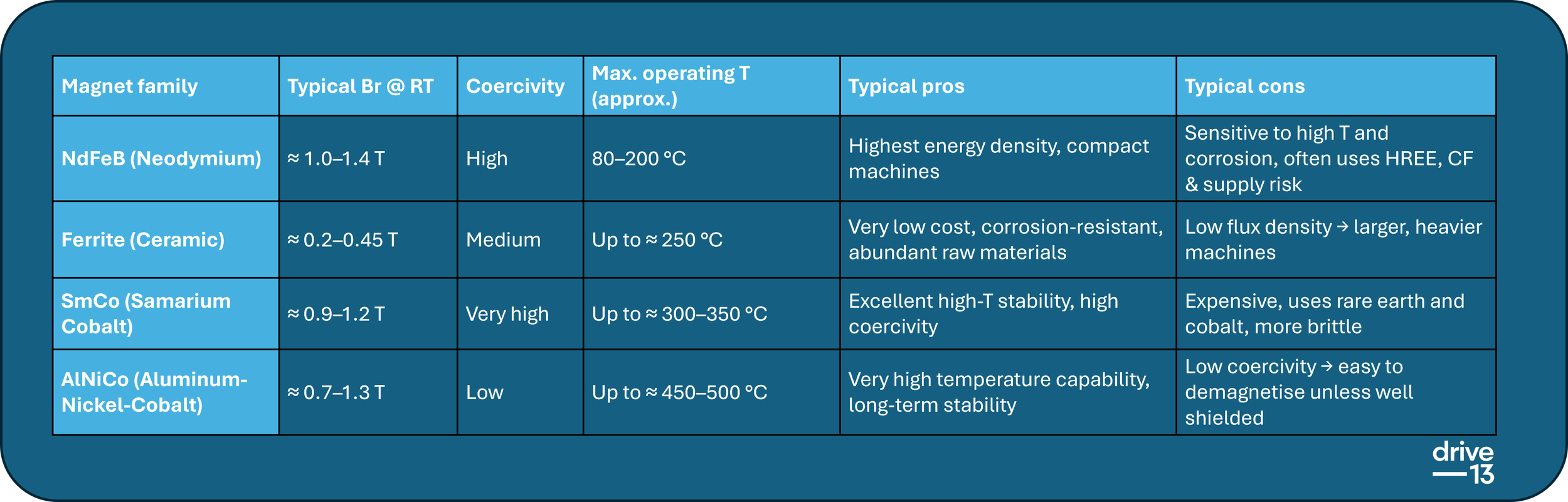

Common Permanent Magnet Families

Below is an overview of the main permanent magnet families used in electrical machines. Values are depend on exact grade and geometry.

Magnet families at a glance:

Temperature-Resistant Magnets

For many e-drives, the limiting factor is temperature, not room-temperature strength.

A useful rule of thumb:

At room temperature, NdFeB usually delivers higher flux than AlNiCo.

At elevated temperatures, the situation changes: AlNiCo and SmCo can outperform NdFeB in retaining magnetisation and resisting demagnetisation.

Key points:

AlNiCo

Lower coercivity at room temperature, but

Very high Curie temperature (up to ~1200 °C)

Can operate above 500 °C without losing permanent magnetism if properly designed

Long-term stability: a newly magnetised AlNiCo magnet loses only a very small fraction of its flux over time (≈ 1 % in 100 years under stable conditions).

SmCo (Sm₂Co₁₇ and related grades)

High coercivity and good corrosion resistance

Curie temperature up to ~700 °C

Commonly used where continuous operation around 250–350 °C is required.

NdFeB

Curie temperature up to ~300 °C (depending on grade and composition)

Practical operating temperatures are usually limited to 80–200 °C; above this, both reversible and irreversible losses become critical unless heavy rare earth doping is used.

So if you rank them by Curie temperature:

NdFeB up to ~300 °C → SmCo up to ~700 °C → AlNiCo up to ~1200 °C

But the usable operating temperature is always lower than the Curie temperature and must be verified in the real electromagnetic and thermal design.

This table shows the relative strengths of Permanent Magnets classified based on thier maximum operating temperture limit:.

| Grade | Max. Op. Temp (°C) | Br (T) max | Br (T) min | Br (kGs) max | Br (kGs) min | bHc (kA/m) | bHc (Oe) | iHc (kA/m) | iHc (Oe) | (BH)max (kJ/m³) max | (BH)max (kJ/m³) min | (BH)max (MGOe) max | (BH)max (MGOe) min |

|---|

Why Material Selection Matters

High-performance e-drive systems (traction motors, aerospace actuators, high-speed compressors, etc.) face multiple constraints at once:

High torque density

Tight thermal envelope

Transient overloads and fault conditions

Weight and packaging limits

Life-cycle CO₂ and critical raw materials (CRM) constraints

That is why material selection cannot be an afterthought. It has to be embedded in the overall system design.

At Drive13, special care is taken with:

Material selection across rotor, stator, and housing

Strategic use of rare earth elements for demanding applications

The goal is to use critical raw materials selectively — just enough to:

Cut supply risk and cost

Maintain or improve top performance

Reduce environmental impact over the full life cycle

From Materials to Systems

(How This Translates into Practice)

In real projects, magnet choice is part of a broader co-design process.

Material trade-offs for the right balance

Through multidisciplinary design optimization, it is possible to:

Co-optimize stator and rotor materials (steel, copper/aluminium conductors, magnets, coatings)

Reduce core losses, torque ripple, and mass simultaneously

Experiment with different magnet families and grades in virtual prototypes

Manufacture and test samples to validate core losses, BH curves, and thermal behaviour

Towards sustainable green permanent magnets

From the concept stage to validated parts, design teams can:

Optimize magnet material, shape, mass, and cost for the actual duty cycle

Explore options from high-coercivity PMs (for compact, high-stress designs) to recycled or lower-footprint routes (for greener supply chains)

Apply heavy rare earths only where they deliver clear, measured gains in performance or reliability

The result is not just a strong magnet on a datasheet, but a well-balanced, power-dense, energy-efficient drive that respects both technical and environmental constraints.

So… What Is Your Best Magnet?

There is no single universal answer. Your best magnet is the one that:

Meets your torque and power targets

Survives extreme temperature scenarios

Minimizes demagnetization risk over the full lifetime

Fits within your cost and supply-chain constraints

Aligns with your sustainability goals

Tools like “Select your Champion Green magnet”, combined with rigorous material and system-level design, help you navigate this landscape quantitatively instead of by guesswork.