Racing Motors

Pioneering Energy-Efficient Motor Design for Demanding Applications

In demanding applications such as electric racing, speed, efficiency, and performance are critical. Advanced manufacturing—and particularly additive manufacturing—plays a critical role in meeting these challenges. By enabling rapid prototyping, design flexibility, and the integration of complex cooling and structural features, additive manufacturing drastically reduces lead times while enhancing performance. These technologies allow for the production of highly optimized components that push the boundaries of what is possible in terms of power density, thermal management, and lightweight design—key factors in gaining a competitive edge on the track.

Drive13 racing motor design

Drive13 collaborates closely with the Electrical Machines research group, at Ghent University, to accelerate the development of cutting-edge electric motors for racing applications. As an industrial partner, Drive13 manufactures and delivers fully functional E-motor components, supporting the process from early-stage design to final implementation. This collaboration enables the rapid delivery of novel concepts with exceptionally short lead times, ideal for the fast-paced demands of racing. Through continuous development and innovation, Drive13 is committed to pushing the boundaries of power density and performance in next-generation electric drivetrains.

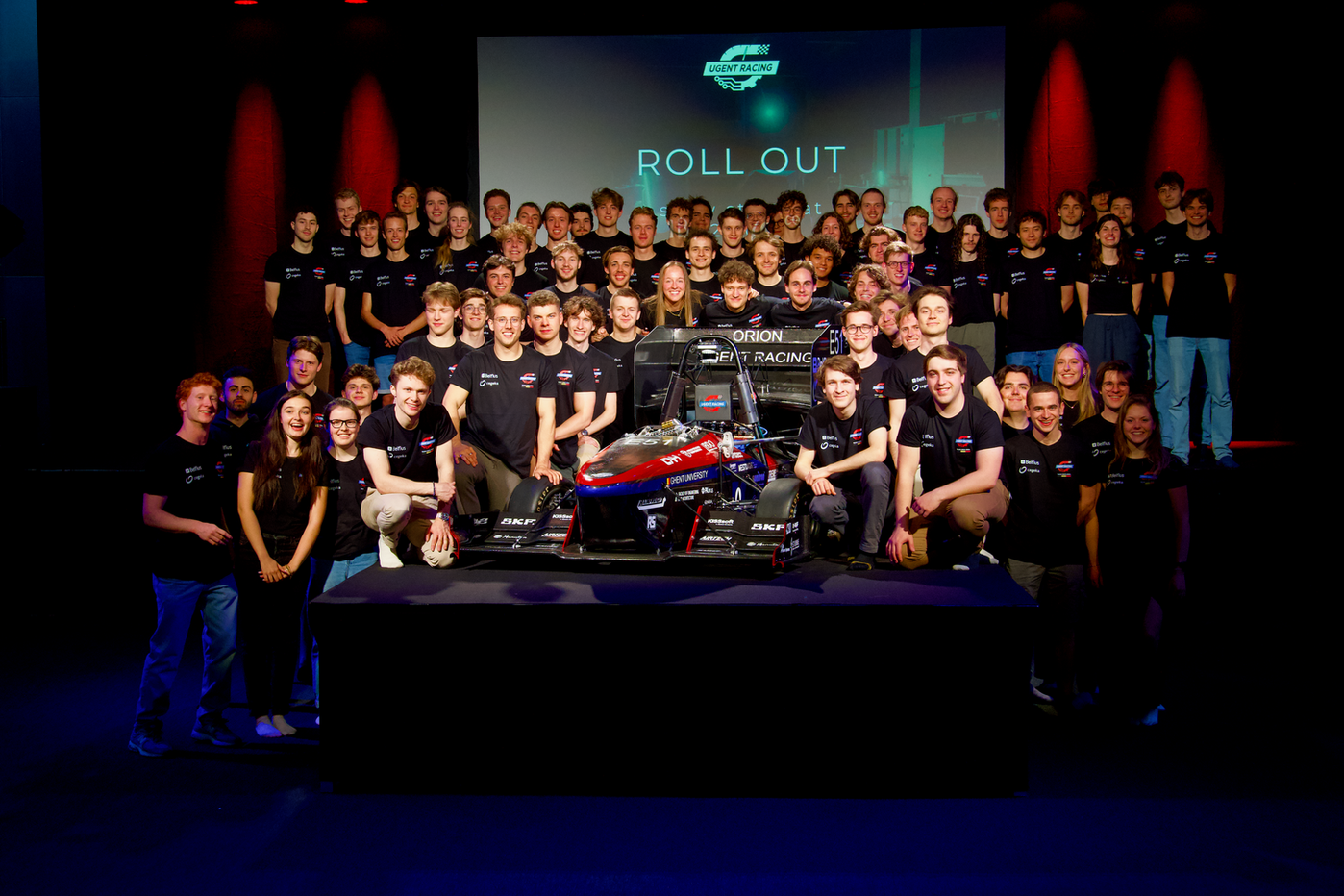

UGent Formula-E Racing Team

UGent Racing is the Formula team of Ghent University. Students from different fields of study and disciplines work together on an electric, autonomous race car. By putting theoretical knowledge into practice, these ambitious and talented members can fully develop themselves through our project-based approach with a strong focus on innovation.